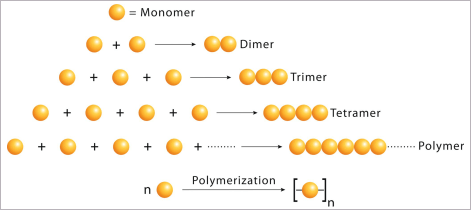

Polymerization is the process by which a monomer or a mixture of monomers is converted into a polymer. This method is widespread in olefin and petrochemical plants where various polymers are generated using various procedures.

Multiple factors, such as flow rates, temperature, fluid characteristics, and so on, can cause severe fouling in process equipment during polymerization operations. The fouling potential increases twice for every 10 degrees Celsius increase in temperature.

The main area of fouling in these sectors is reboilers. Reboilers heat the liquid at the bottom of the distillation column, generating vapors that are recirculated back into the column to keep the distillation process going.

Vertical heat exchangers are most commonly used, with the process stream entering from the bottom of the tube side and steam / or hot oil on the shell side.