Click on the image to enlarge

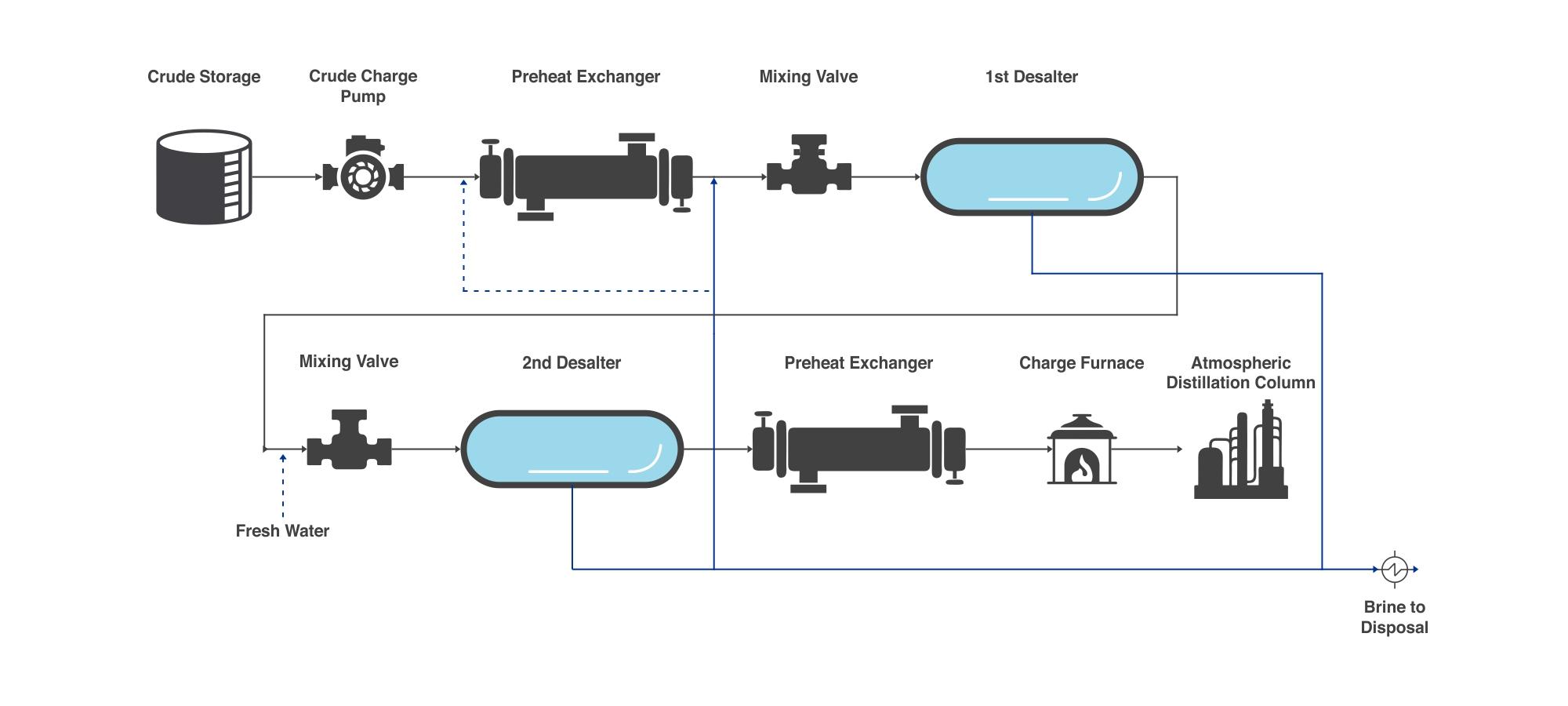

Fouling in Crude preheat and desalter brine heat exchangers is a very common phenomenon in all crude units in the oil refinery. The severe fouling problems are being observed when refiners process heavy or incompatible crudes.

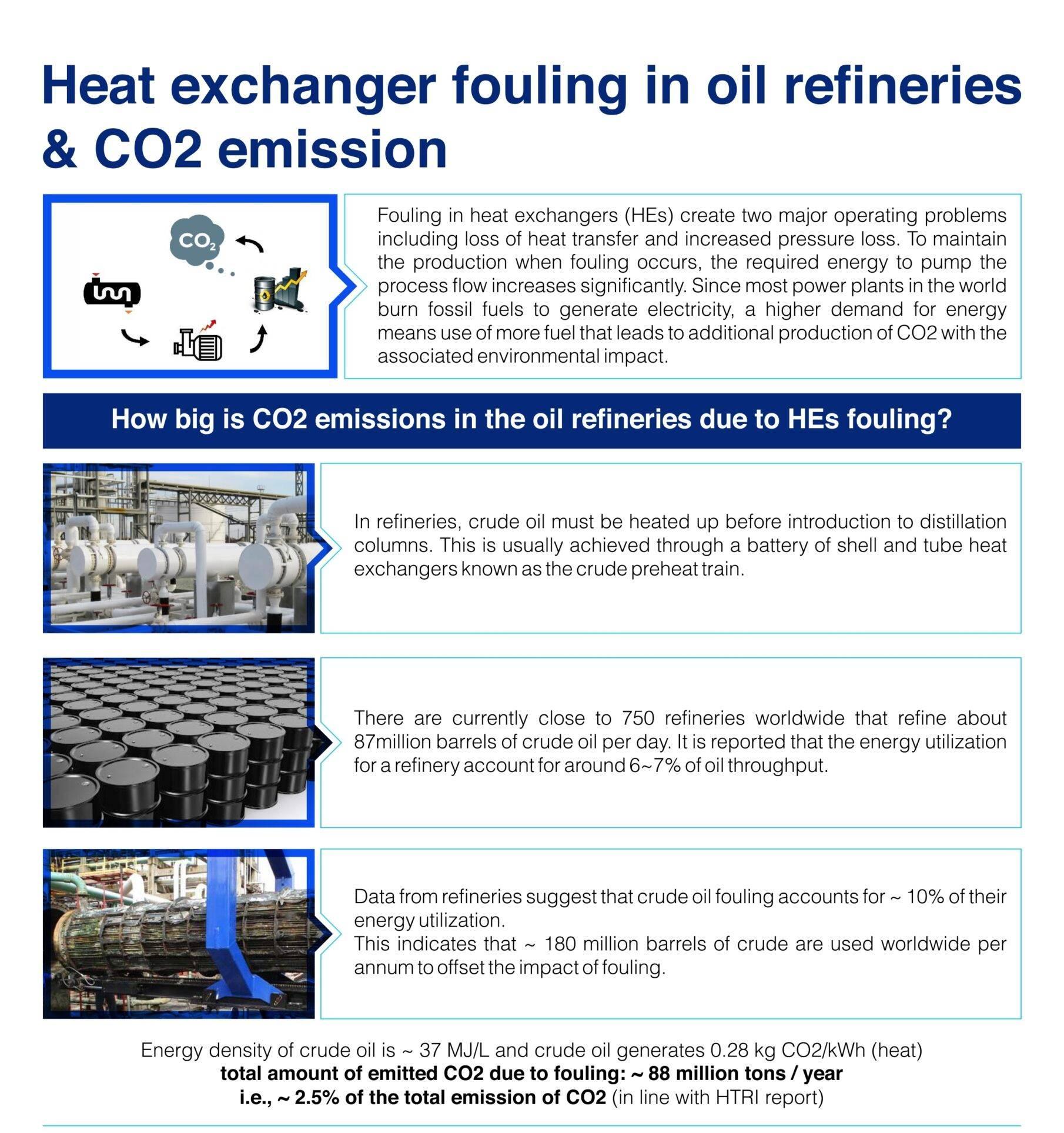

Asphaltene deposition is the primary cause of fouling in crude preheat exchangers, which is generally minimized by oversizing, redundant equipment, and/or the use of antifoulant chemicals. Aside from production losses, fouling causes a drop in the furnace Inlet temperature (FIT), which adds additional fuel burning and hence greater energy costs to maintain optimal crude column operations.

In many cases, due to malfunctioning of desalter operations, high oil under carry and/or suspended solids in brine causes fouling in the brine heat exchangers. Often, these heat exchangers heat fresh water which helps to remove salts from desalters and better desalting efficiency. The fouling of this system causes low inlet temperature of fresh water which in turn affects desalter operation and hence poor desalting.

We understand that, in the refining industry, the conventional heat exchanger arrangement is horizontal and the KLAREN technology requires a vertical S&T heat exchanger. With a vertical configuration it has been proven that the KLAREN technology can keep the heat exchanger clean when heating up crude oil.

Please feel free to contact us for a feasibility assessment and detailed discussion about the KLAREN self-cleaning heat exchanger technology.