Click on the image to enlarge

Reboilers are heat exchangers applied to provide heat to the bottom of distillation columns in several industries such as food, chemical, textile, paper, sugar, oil field, oil refining, power plants. The liquid from the bottom of a distillation column is heated in the reboiler and returned to the column to drive the distillation process. The common types of reboilers used are shell-and-tube thermosyphon, forced-circulation, kettle, and fired reboilers. Most reboilers are of the shell and tube heat exchanger type and normally steam is used as the heat source in such reboilers. In some cases, thermal oil is also used as a heating medium.

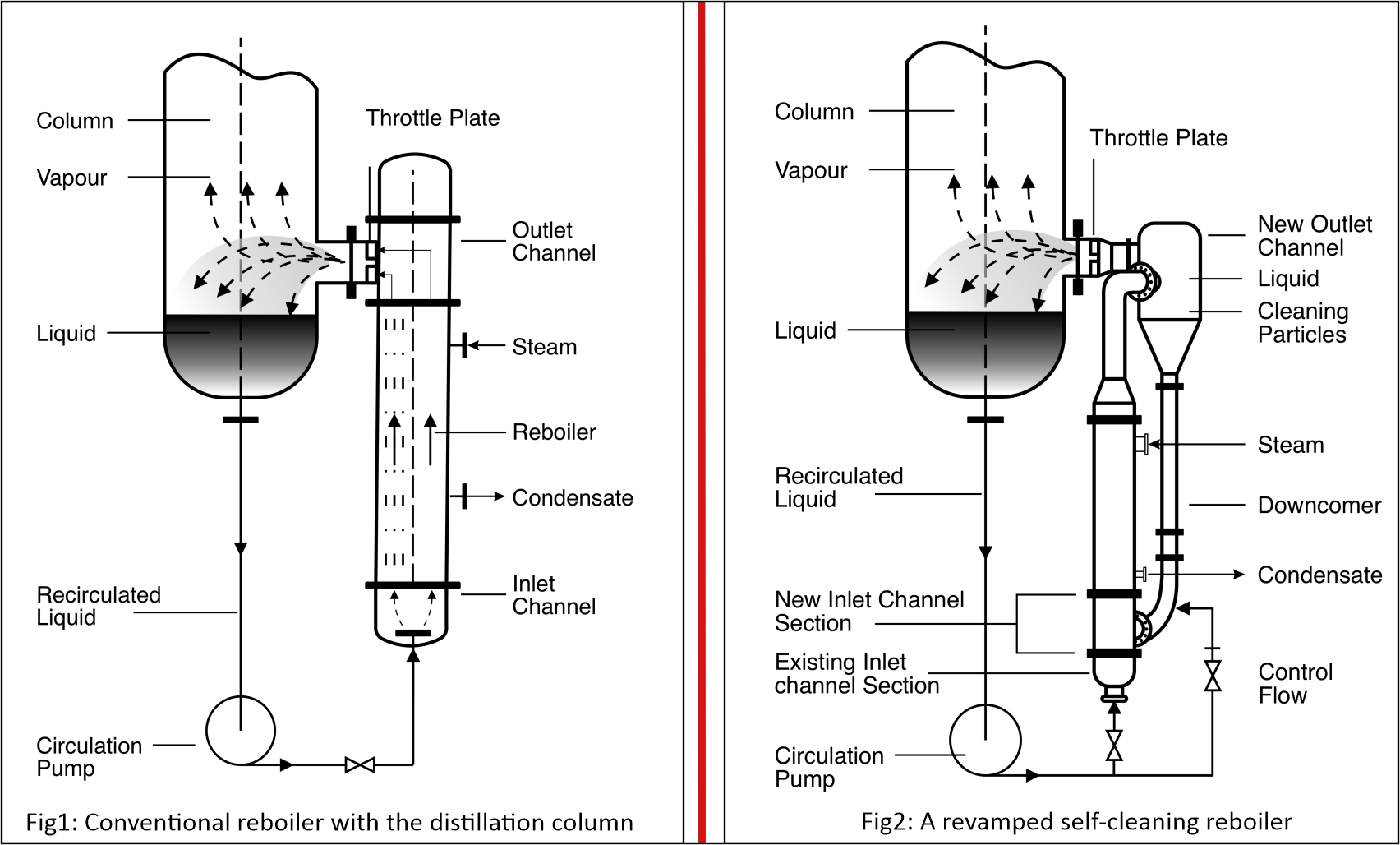

Klaren’s self-cleaning technology can be applied to vertical configuration forced circulation type reboilers. In the forced circulation type, a pump between the distillation column bottom and reboiler is placed. This mechanism is popular for high viscosity or high fouling services.

The efficient operation of a reboiler is vital for an effective distillation process. Fouling is one of the greatest problems that affect all different types of reboilers. Foulants that cause fouling in reboilers include dirt and corrosion products that come from plug tubes or scales of heat transfer surfaces. Fouling degrades the performance of the reboiler by decreasing the heat transfer coefficient and implies economic and energy losses and interruption of the process for cleaning.

Existing vertical conventional reboilers that are subject to heavy fouling can be revamped to a self-cleaning configuration at a relatively low cost. A typical conventional reboiler under consideration for revamping is shown in Figure 1. Depending on the process and operating parameters, these reboilers tend to foul. Foulants that cause fouling in reboilers include dirt, polymers, and corrosion products that come from plug tubes or scales of heat transfer surfaces. This reduces the performance of the reboiler and hence poor distillation process.