What is Fouling In Heat Exchangers

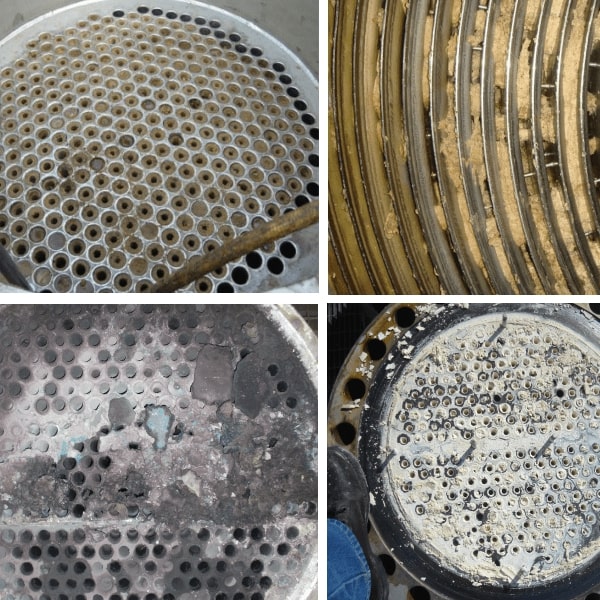

The deposition of unwanted materials, such as scale, suspended solids, insoluble salts and even algae on the internal surfaces of the heat exchanger is called fouling. The presence of these deposits represents a resistance to the fluid flow and heat transfer and therefore increase the pressure drop and reduces the efficiency of the heat exchanger. The degree of fouling varies considerably with physical properties of fluids being handled. In severe fouling conditions, the heat exchanger may become blocked and hence inoperable because of the back pressure. Depending on the fouling deposits involved, they can lead to corrosion of the heat exchanger which can often be hidden by the fouling layer itself. This shortens the working life of the heat exchanger and can result in catastrophic failure.

Types of fouling

There are different types of fouling, which can vary according to several factors, such as the operating conditions in which the heat exchanger is used. There are also different terms used globally for the different types of fouling and this can lead to confusion about what is happening in a particular situation. In simple terms the foulant may be crystalline, biological material, the products of chemical reactions including corrosion, or particulate matter. The character of the deposit depends on the fluid (liquid or gas) passing through the heat exchanger. It may be the bulk fluid itself that causes the problem of deposit formation, e.g., the decomposition of an organic liquid under the temperature conditions within the heat exchanger. The fouling problem is produced by some form of contaminant within the fluid, often at very low concentration, e.g., solid particles or micro-organisms.

Fouling can occur because of the fluids being handled and their constituents in combination with the operating conditions such as temperature and velocity. Almost any solid or soft material can become a heat exchanger foulant, but some materials that are commonly encountered in industrial operations as foulants include: inorganic materials, airborne dusts and grit, waterborne mud and silts, calcium and magnesium salts, iron oxide, organic materials, biological substances, e.g., bacteria, fungi and algae, oils, waxes and greases, heavy organic deposits, such as polymers, tars and carbon.

Fouling Factor

The fouling factor represents the theoretical resistance to heat flow due to the buildup of a fouling layer on the tube surfaces of the heat exchanger. In practice, fouling factor is often overstated by the end user to minimize the frequency of cleaning. If the wrong fouling factor is used, cleaning may be required more frequently. The fouling factor, which is usually shown as Rshell or Rtube [m2K/W]) represents the thermal resistance of the fouling layer as a ratio between the heat transfer coefficient of a clean heat exchanger and the same unit after fouling.

Standard values are available for several common liquids and gases such as fuel oil, seawater and alcohol vapor. However, for many materials, with the highest fouling factors such as sludges, it is best to analyze the substance to achieve an accurate result.

Fouling cost

Economic aspect of heat exchanger fouling is quite important as this will affect the operating costs that in turn affects the profitability of the operation. In the first instance the heat exchanger is generally overdesigned to allow for the incidence of fouling. Increasing the size of the exchanger will of course, increase the initial capital cost and hence the annual capital charge.

To overcome the effect of flow restriction due to the fouling for a given throughput, the velocity will have to increase which represents an increase in pumping energy and costs. Many pumps are electrical and so the increased energy requirement is in terms of the more expensive secondary energy. Other operating costs can accrue from the presence of the deposits such as increased maintenance requirements or reduced output.

unplanned shutdown as a direct result of heat exchanger fouling can be particularly expensive. In many examples of severe fouling the frequency of

cleaning may not coincide with planned periodic plant shut down for maintenance (annual basis) and it might be necessary to install standby heat exchangers for use when the cleaning of heat exchangers becomes necessary. Additional heat transfer capacity provided by standby equipment represents an additional capital charge.

Fouling removal

Despite the best efforts of engineers and technologists to eliminate heat exchanger fouling the growth of deposits will still occur. Periodic cleaning of the heat exchangers will be necessary to restore the heat exchanger to efficient operation. If the deposits are difficult to remove by mechanical means chemical cleaning may be required. The chemicals used for this purpose will often be aggressive in character and represent an effluent problem after the cleaning operation. Unless this effluent is properly treated it could also represent an environmental problem. Even water used for cleaning can become contaminated and may require suitable treatment before discharge.

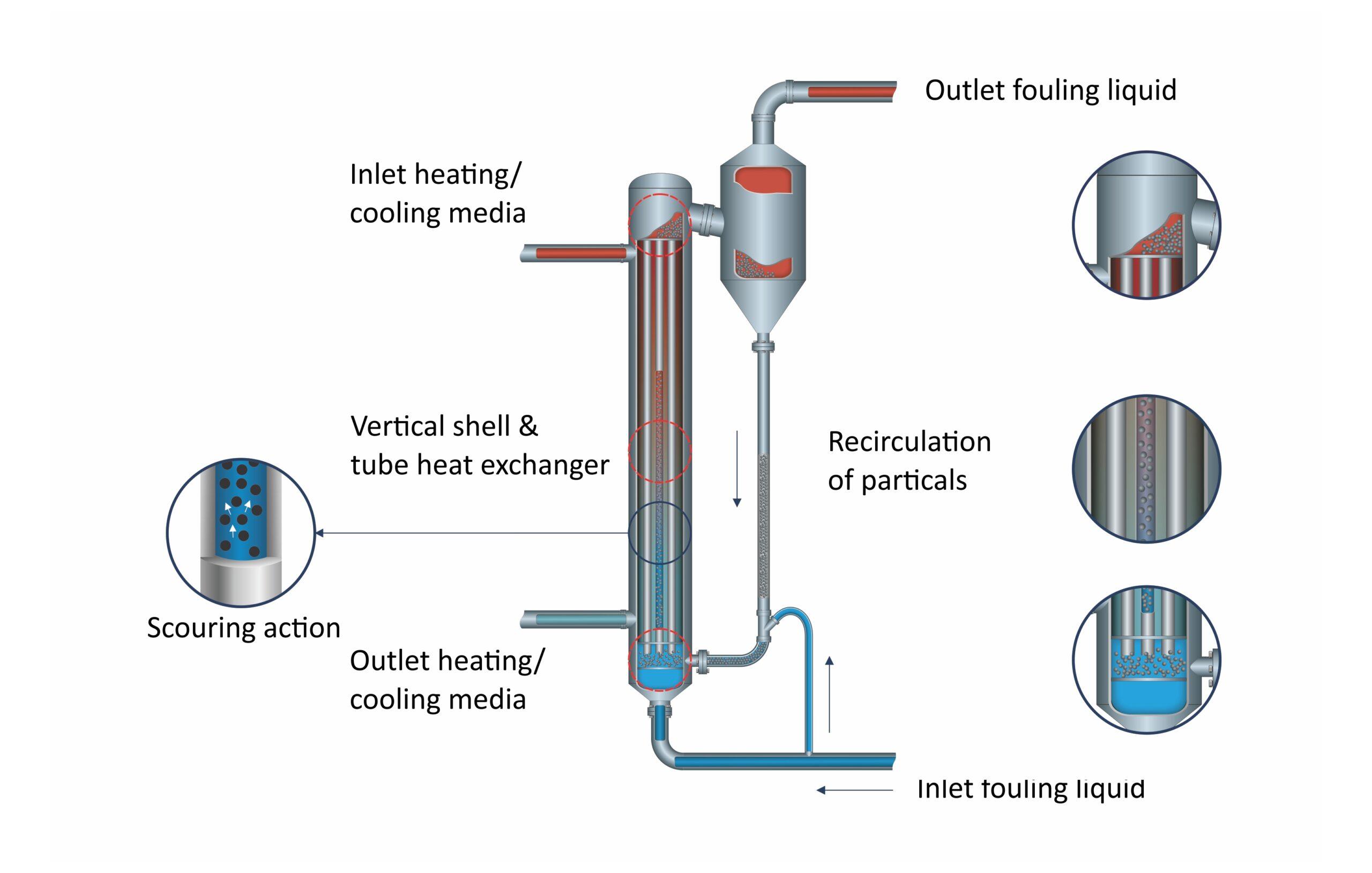

However, in all cases, fouling prevention/reduction is more effective and also cheaper compared to the cure, i.e., fouling removal and heat exchanger cleaning. Taprogge offers innovative self-cleaning fluidized bed heat exchanger that prevents fouling in the early stages. With Taprogge’s Klaren self-cleaning heat exchanger technology, you can achieve up to zero fouling operations in your liquid stream, keep system clean and run plant without any operational constraints.