Self-Cleaning Heater

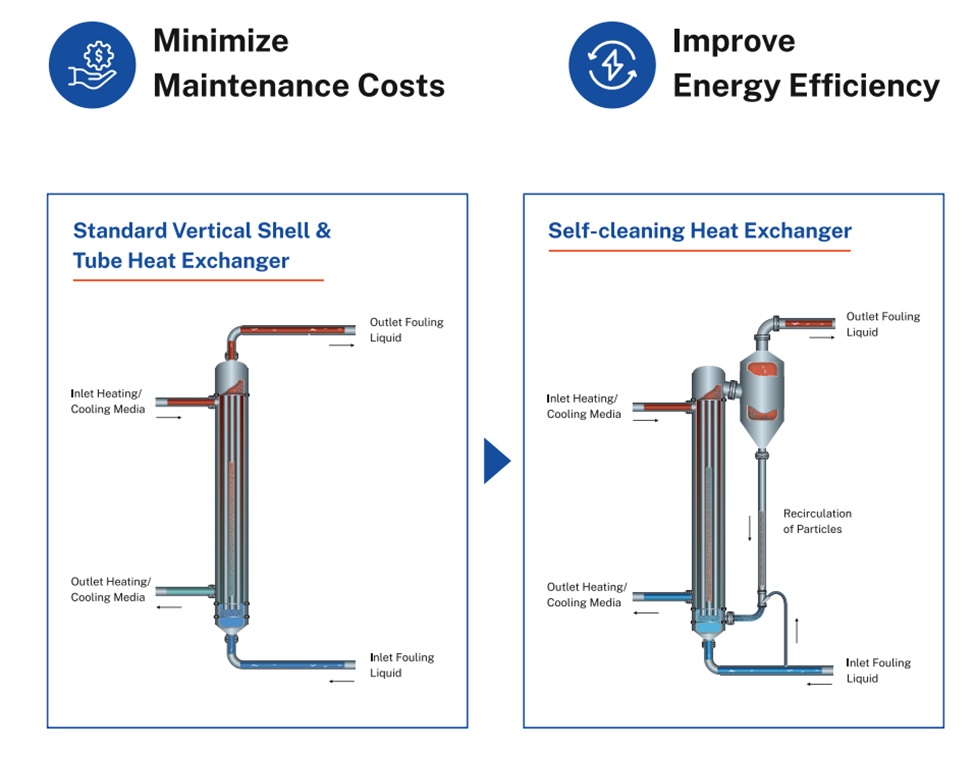

The Self-Cleaning Heater is a game-changer for industries using shell and tube heat exchangers that often get fouled on the tube side. New as well as existing heat exchangers can be equipped with the self-cleaning configuration. It’s especially beneficial for the Chemical and Oil & Gas sectors, helping maintain efficient heat transfer while reducing maintenance downtime. Keep your operations running smoothly with our Self-Cleaning Heater.

Self-Cleaning Cooler

The Self-Cleaning Cooler works similarly to the heater, but for cooling processes with fouling challenges on tube side. Whether it’s due to chemical reaction or temperature changes, the technology ensures reliable operation and desired efficiency. Industries like chemicals and mining can count on this technology to keep their heat exchanger performance consistent, prevent fouling-related issues, and maintain smooth production. Elevate your cooling processes with the reliability and innovation of the Self-Cleaning Cooler.

Self-Cleaning Evaporator

The advanced Self-Cleaning Evaporator is designed to maintain constant evaporation rate and smoother operations for industries. By preventing buildup/fouling that causes disruptions, the technology cut down on maintenance needs, ensuring steady production. This modern solution can easily fit into your existing evaporators or enhance new Multi-Effect Evaporator (MEE) and Mechanical Vapor Recompression (MVR) Evaporator Systems.

Self-Cleaning Crystallizer

The Self-Cleaning Crystallizer operates on a similar principle to our acclaimed Self-Cleaning Evaporator, but with a specific focus on crystallization processes. An evaporator concentrates a solution by removing the solvent, while a crystallizer promotes the formation of solid crystals from a saturated solution. Engineered to combat fouling challenges that commonly hinder crystallization operations, this product promises efficiency, reliability, and innovation.

Self-Cleaning Reboiler

The Self-Cleaning Reboiler is tailored for vertical forced circulation type reboilers. For highly viscous liquids when fouling is a concern, it uses a pump between the distillation column and reboiler to keep things flowing well. This smart upgrade transforms your current vertical reboilers, which might have fouling issues, into self-cleaning versions to keep the operation running smoothly. Elevate your reboiling processes with improved efficiency and longer equipment life.

Self-Cleaning Condenser

The Self-Cleaning Condenser, much like its counterpart the Self-Cleaning Cooler, is designed to excel in specific applications, catering to industries that rely on efficient vapor condensation while combatting the challenges posed by fouling on tube side minimizing downtime and maximizing productivity.

HELIKLAREN

The HELIKLAREN presents an innovative solution to enhance energy efficiency and meet sustainability targets. This comprehensive solution optimizes heat transfer on both shell and tube sides, revolutionizing your processes, by combining helical baffles (shell) with the KLAREN fluidized bed technology (tube). The special helical baffles on the shell side reduce pressure drop, thus reducing energy usage while improving heat transfer operation. In addition, the fluidized bed on the tube side prevents fouling layers on the metal surfaces, ensuring smooth operation.