The cost of refining vegetable oil is heavily influenced by energy use. Recovering heat from refined oil and using it to pre-heat other oil streams in the plant contributes to a more energy-efficient operation.

Crude vegetable oil components such as particulates, filter media particles, dust, waxes, or other physical impurities/contaminants may foul the heat exchangers. Heat exchanger fouling limits the amount of heat that can be recovered, increasing energy consumption as well as maintenance and cleaning. Fouling also increases the resistance of the fluid moving through the tubes. These side effects work together to raise the pressure drop across the heat exchanger, lowering flow rates and intensifying the problem.

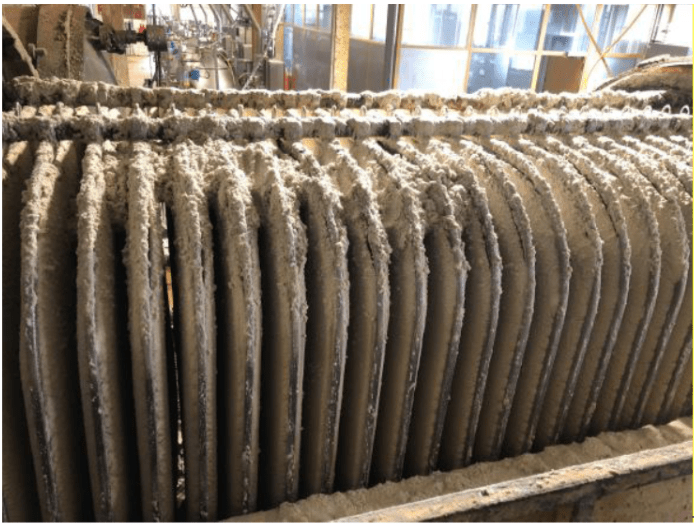

The KLAREN self-cleaning heat exchanger technology offers a proven cleaning solution for new or existing heat exchangers in edible oil refineries. The self-cleaning arrangement is applicable to all types of vegetable oil companies. At the tube side of the self-cleaning heat exchangers, where the fouling liquid runs through, a fluidized bed of solid particles is used. The solid particles scour the surface of the tube wall, removing the growing fouling layer. This prevents shell and tube heat exchangers from becoming severely fouled.