Innovative solution to indirect heating in High-Pressure-Acid-Leach Process (HPAL)

This article explores the application of self-cleaning fluidized bed heat exchangers, specifically designed to address these challenges in the context of HPAL plants. Indirect heating methods have long been sought after for their numerous advantages over direct heating in High-Pressure-Acid-Leach (HPAL) plants, particularly in the extraction of valuable metals like nickel and cobalt from laterite ores. However, traditional indirect heating approaches present challenges such as heat transfer inefficiency, temperature control issues, equipment complexity, and the risk of corrosion and fouling.

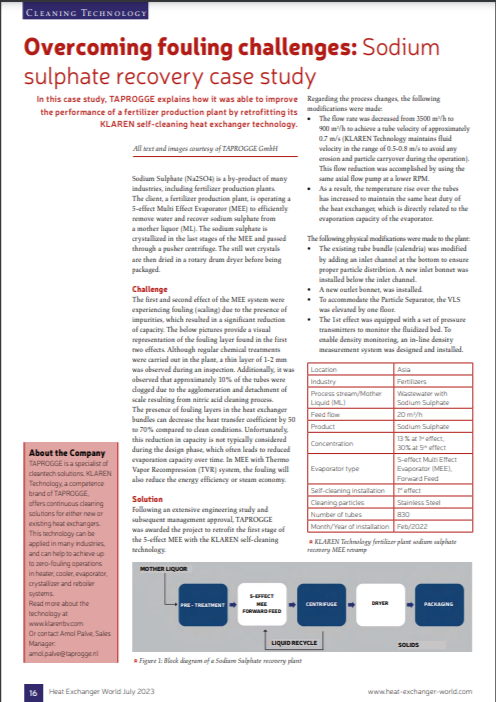

Overcoming fouling challenges: Sodium sulphate recovery case study

In this case study, Taprogge explains how it was able to improve the performance of a fertilizer production plant by retrofitting its KLAREN self-cleaning heat exchanger technology. The KLAREN self-cleaning heat exchanger technology has improved the plant’s performance significantly by preventing fouling and keeping the tubes in the first effect clean. Multiple inspections, in the first year after installation, confirmed that the tubes remained clean.

An improvement in steam economy by 5-10%, And A 10% increase in the feed flow rate to the multi-effect evaporator (MEE) are observed.

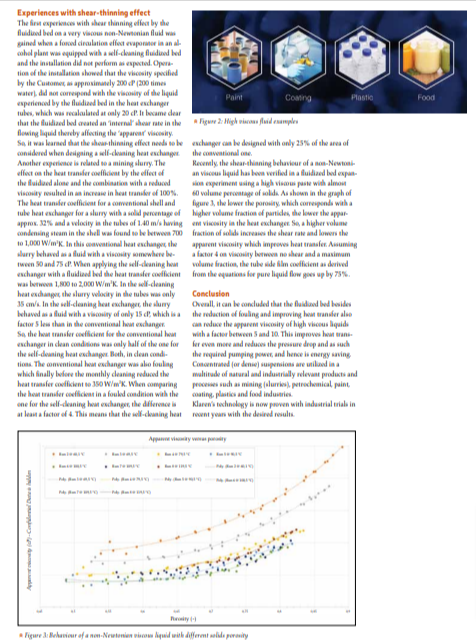

KLAREN Fluidized Bed Technology: Reducing viscosity by shear thinning

This article discusses that the fluidized bed besides the reduction of fouling and improving heat transfer also can reduce the apparent viscosity of high viscous liquids by a factor between 5 and 10. This improves heat transfer even more and reduces the pressure drop and as such the required pumping power, and hence is energy saving. Concentrated (or dense) suspensions are utilized in a multitude of natural and industrially relevant products and processes such as mining (slurries), petrochemical, paint, coating, plastics and food industries. Klaren’s technology is now proven with industrial trials in recent years with the desired results.

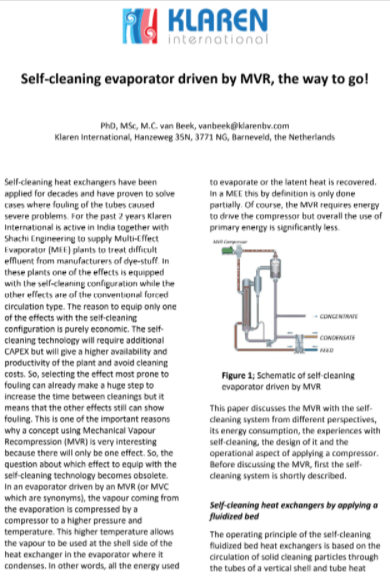

White-Paper Self-cleaning evaporator driven by MVR, the way to go!

This article discusses how one can save 41 % in the use of primary energy when using a Mechanical vapor recompression ( MVR) to treat waste water by concentrating it through evaporation.

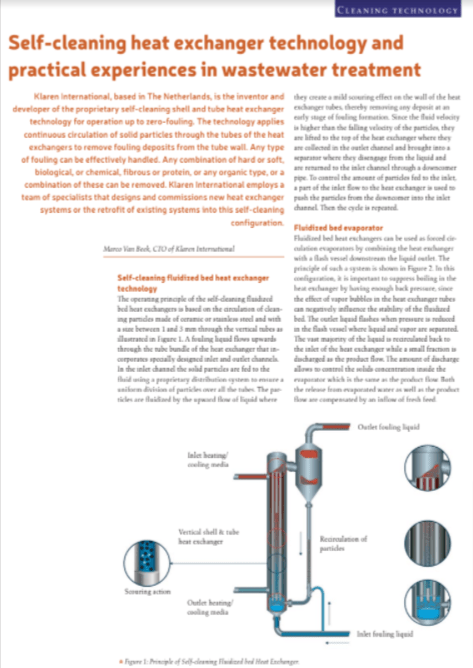

Self-cleaning heat exchanger technology and practical experiences in wastewater treatment

This article provides glimpse of our technology and practical experiences of wastewater industry. It is published in Heat Exchanger world magazine in Nov’2021 issue.

Self-cleaning evaporator driven by MVR – the way to go!

Janwary 2021

Published in Jan 2021 in chemical weekly issue, our Indian partner Shachi talks about Mechanical vapor recompression (MVR) and evaporation.

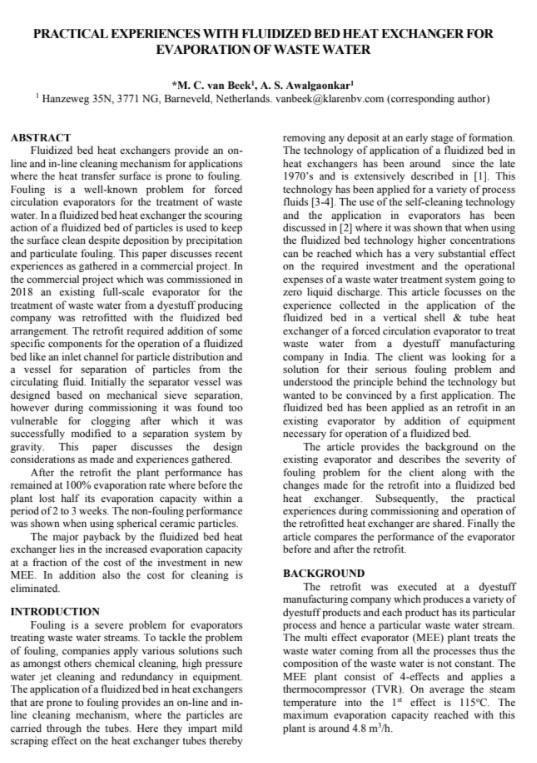

Practical Experiences With Fluidized Bed Heat Exchanger For Evaporation Of Waste Water

2019

Presented in 2019 at Heat Exchanger Fouling & Cleaning conference XIII in Poland, Taprogge deep dive into fluidized bed heat exchangers basics and explain evaporator revamp case in detail

Fluidized Bed Heat Exchangers For The Evaporation Of Waste Waters: Design Advantages And Operational Experiences.

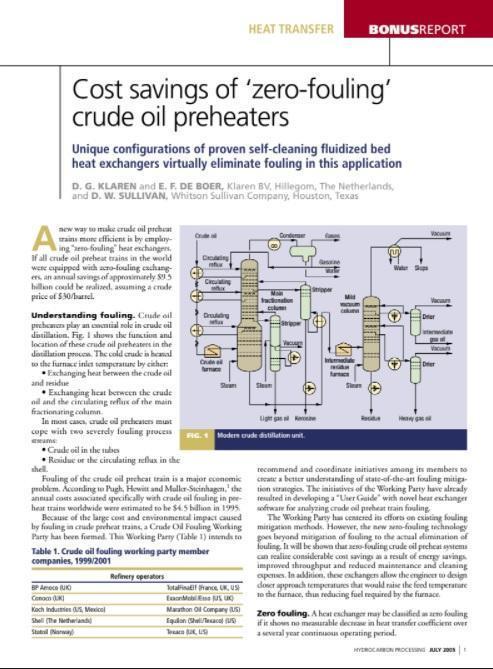

Cost savings of ‘zero-fouling’ crude oil preheaters

2005

Published in 2005 at Hydrocarbon processing magazine, our founder Dr. D G Klaren talks about unique configurations of proven self-cleaning bed heat exchangers in crude oil preheaters

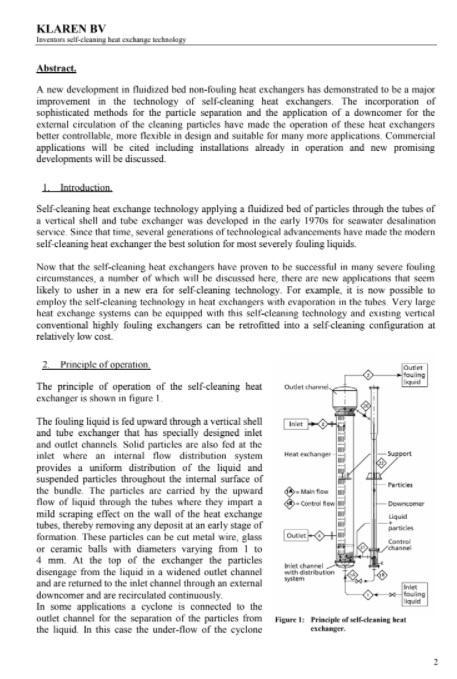

Self-Cleaning Heat Exchangers: Principle, Industrial Applications And Operating Installations

2000

Published in 2000 at Industrial Heat Transfer Conference, Dubai, our founder Dr. D G Klaren talks about early technology development ideas, applications and installations.

Use Of Flue Gases From Open Cycle Gas Turbines To Drive MSF Plants, Pilot Test With Fluidized Bed Heat Exchanger

2017

Presented in 2017 at Heat Exchanger Fouling & Cleaning conference XII in Spain, This paper presents the tests performed in 2015 and 2016, at Sabiyah Thermal Power and Desalination Plant with a fluidized bed self-cleaning heat exchanger test unit. This unit has been designed to test the non-fouling performance of the fluidized bed self-cleaning heat exchanger technology when heating up hot brine using flue gases at high temperatures of approximately 550 oC.