It is predicted that the population will double in the next 30 years. As a result of the growth in population, the demand for water resources has increased. And, as we all know, water is required at every stage of the manufacturing and production process all over the world. Nearly 40% of water consumption is accounted for by industries. In order to address the current water scarcity, enterprises are repurposing wastewater treatment water.

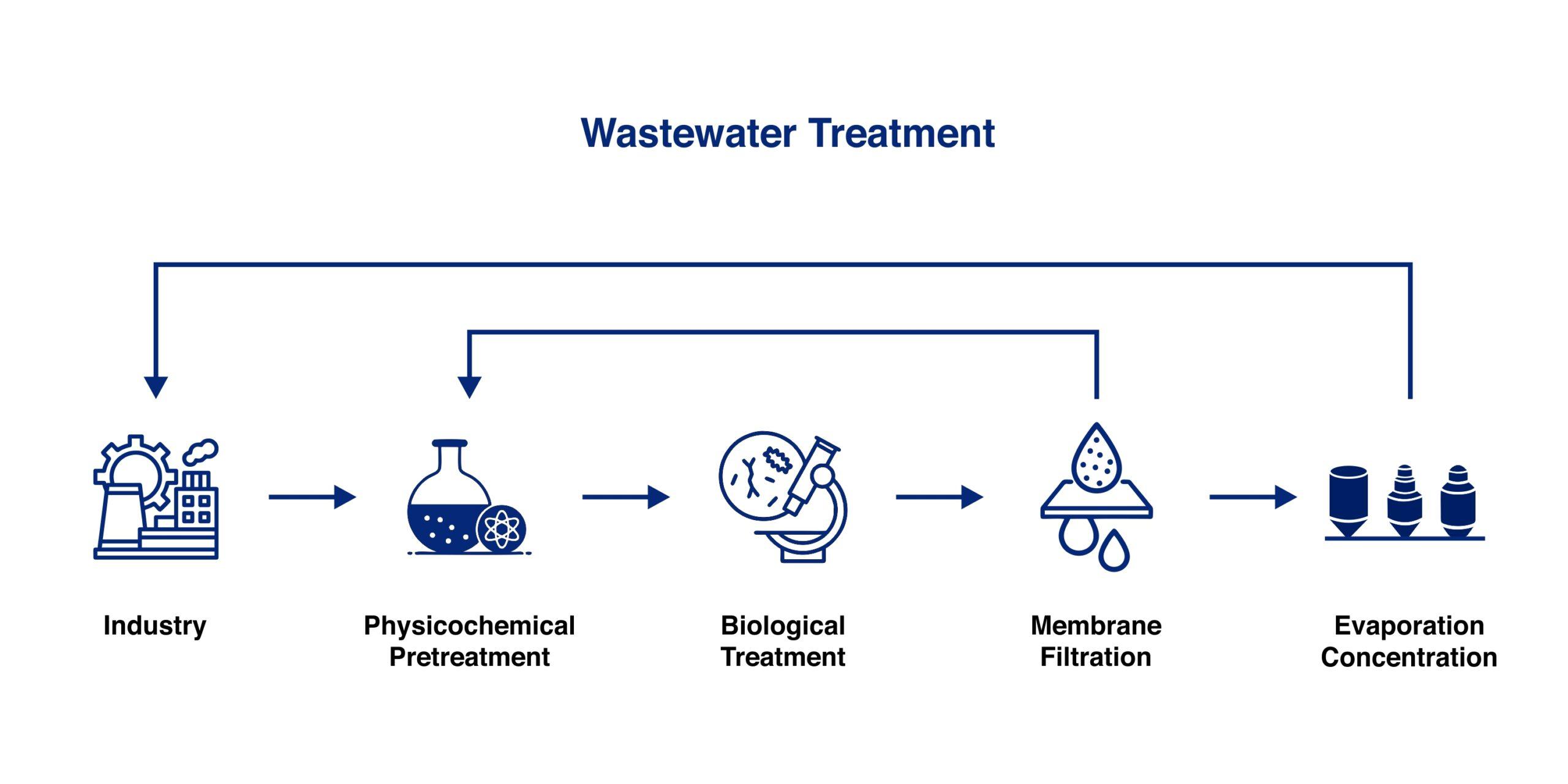

There are various processes included in treating the wastewater such as physicochemical pretreatment, Biological treatment, membrane filtration, and evapocentration. During this process after membrane filtration, the water is further processed by evaporation to recover maximum water from the reject. Due to the salts and sediments in the reject water MEE (Multi effective Evaporators) or MVR (Mechanical Vapor recompression) tends to foul which results in a decrease in heat transfer efficiency and an increase in operational expense for maintenance.

With the several successful experiences with Multiple Effect Evaporators (MEE) and Mechanical Vapor recompression (MVR), we are happy to discuss your case and provide a free feasibility report.With the help of Klaren’s self-cleaning heat exchanger technology, you can achieve up to zero fouling operations in your liquid stream, keep the system clean and run the plant without any operational constraints.

Contact us for the feasibility report and further discussion.