Energy consumption is of critical importance in the costs of refining vegetable oil. To recover the heat from refined oil to pre-heat other oil streams in the plant will contribute to a more energy efficient operation.

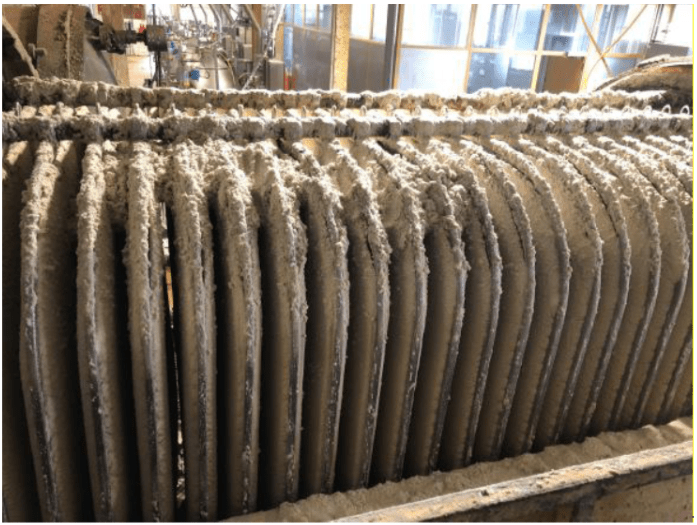

Crude vegetable oil components such as solids, particles from filter media, dust, waxes, or other physical impurities/contaminations could result in fouling of the heat exchangers. Fouling of the heat exchangers reduces the heat that can be recovered, resulting in increasing energy consumption, and maintenance and cleaning. The build-up of fouling also increases the resistance of the fluid passing over the tubes. These side effects combine to increase the pressure drop across the heat exchanger, reducing flow rates and aggravating the problem further.

Klaren International by using proven state-of-the-art self-cleaning fluidized bed technology offers continuous cleaning solutions for either new or revamped heat exchangers in the sunflower oil refineries. The self-cleaning configuration can be realized in all kinds of vegetable oil industries. A fluidized bed of solid particles is used at the tube side of the self-cleaning heat exchangers where the fouling liquid flows through. The solid particles create a scouring effect on the tube wall surface which removes the developing fouling layer. This prevents severe fouling of shell and tube heat exchangers. Our designs operate up to zero-fouling.