Written by Klaren International on .

What is the benefit of a self-cleaning heat exchanger for an evaporator?

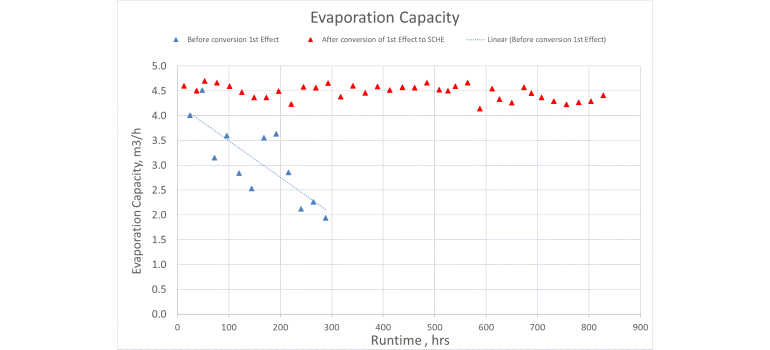

After the first period of operation we can answer this question. The answer comes from the graph that is added to this post. Previous experience of the plant showed that because of fouling of the heat exchanger tubes, the evaporation capacity of the plant reduced with 50% within 12 days of operation. After the retrofit to our technology, using a fluidized bed with cleaning particles, the evaporation capacity remained constant.Before the conversion the average production capacity was only 75% of design. So, with our technology the client has gained 33% production capacity. The benefit would be even greater in case the production loss due to the down-time for cleaning (can take between 2 and 5 days) would be considered as well.When comparing the investment for adding 33% capacity using conventional technology with the investment for a retrofit into the self-cleaning heat exchanger, a decision can be easily made. The investment for a retrofit is a factor of 3 smaller.