Written by Klaren Technology on Aug 27, 2023.

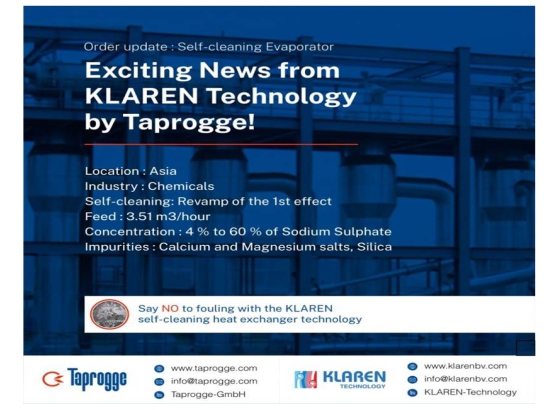

We’re happy to announce that we’ve secured another remarkable order in the prestigious chemical industry of Asia. Our team will be working on the design of a revamp of the 1st effect of a 4-effect existing MEE (Multi Effect Evaporation) plant, designed to handle a complex effluent containing sodium sulfate ( 4 % to 60 % concentration).

One of the challenges faced by the MEE plant is significant fouling, predominantly occurring in the 1st effect. Over time, this fouling has led to a reduction in the evaporation rate, affecting overall efficiency.

Currently, every month (approximately every 15 to 20 days, mechanical cleaning of the evaporator bodies taking place, requiring a considerable 72 hours.

Our team is ready to tackle the challenges and help the client to achieve up to zero-fouling operations.

The benefits of the KLAREN self-cleaning evaporator are:

▸Enhanced Efficiency

▸Continuous Operation

▸Reduced Maintenance Costs

▸Longer Equipment Lifespan

▸Environmentally Friendly

▸Easy Integration

Whether you have an existing forced circulation Multi-Effect Evaporator (MEE) or Mechanical Vapour Recompression Evaporator (MVRE) System, KLAREN self-cleaning Technology can be efficiently retrofitted, tailored to your specific requirements.

Upgrade your MEE and MVR evaporator systems with our advanced Self-Cleaning Technology and embrace a new era of efficiency, sustainability, and convenience.

Learn more about of evaporator solution:

Contact us at info@taprogge.nl

Meet us at the upcoming exhibitions across the world,

- IFAT India: https://www.ifat-india.com/

- Weftec, USA: https://www.weftec.org/

- HEW America: https://heat-exchanger-world-americas.com/

- Aquatech, The Netherlands: https://www.aquatechtrade.com/amsterdam

- Dahej Expo, India: https://www.industrialexpo.co.in/index.html

- Enlit , Indonasia: https://www.neventum.com/tradeshows/power-gen-asia-1

-