Written by Klaren International on .

Produced water is a by-product of oil and gas extraction. Regulations for fresh water recovery from these waters are becoming stricter, which makes operating costs for disposal expensive. Therefore, oil companies are paying more attention to systems to treat this water in an economically efficient way. A combination of forced circulation or falling film evaporation with mechanical vapor recompression (MVR) is a commonly used configuration. Vapor out of one stage evaporator is compressed and used as heat input in the shell side of the evaporator. The condensate can be re-used while the discharge can be further concentrated in crystallizers, dryers or just disposed in solar ponds for further evaporation. In some cases, the remaining liquid discharge is re-injected in wells.

Highly mineralized water is evaporated at high temperatures in the process to treat produced water. The combination of high mineral concentration and high temperatures causes these water solutions to precipitate minerals which crystallize as a scaling layer on the walls of the heat exchangers of the evaporators. Fouling of heat exchangers in this application results in:

- Production losses or reduced operation capacity

- Over sizing and / or redundancy of equipment

- Increase in maintenance costs

- Disposal of waste streams from using cleaning chemicals

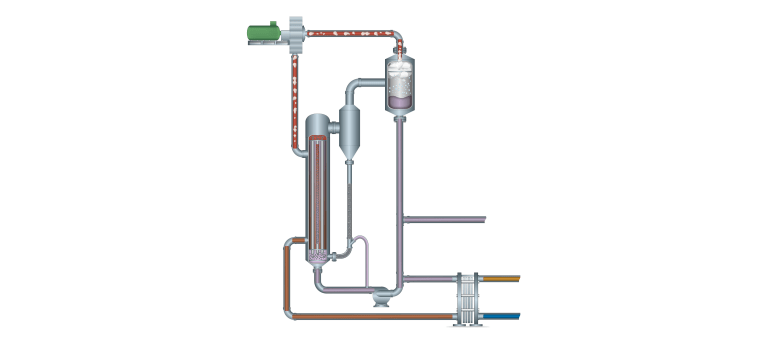

A common practice to reduce the fouling effects in produced water evaporation is to use expensive softening pre-treatment plants and to limit the mineral concentration levels due to the relation between mineral concentration and fouling tendency. This adds a constrain into the maximum produced water volume reduction that can be achieved through evaporation.To avoid problems associated with fouling and to be able to further concentrate produced water above typical concentration levels, fluidized bed heat exchangers can be used. Fluidized bed heat exchangers can be used as forced circulation evaporators by combining a regular fluidized bed heat exchanger and a flash vessel downstream the liquid outlet. And can be integrated not only in MVR configurations but also in thermo-compressor or multiple effect evaporator trains.

The capital cost of evaporation systems including fluidized bed heat exchangers is lower than of conventional forced circulation or falling film systems. This is because there is no need for expensive softening systems prior to evaporation and redundancy is not required. When a downstream Zero Liquid Discharge (ZLD) stage (crystallizer or dryer) is installed, the capital cost difference is larger. If a fluidized bed heat exchanger is used it can lower size requirements of these systems. Operating costs are also lower due to lower costs of treatment or disposal of the evaporator discharge.More details on this topic have been presented at the Heat Exchanger Fouling and Cleaning XII – 2017 conference in Madrid, Spain, on June 11-16, 2017. A full detailed paper is available.